O&M (Operation and Maintenance) Service

O&M (operation and maintenance) for offshore wind power generation is much more difficult than that for onshore facilities, and the impact of equipment failures will be greater and more critical.

We have provided EPC and O&M services for various power generation facilities, including onshore wind power generation facilities. Through handling large-scale plants, we have refined our remote monitoring technology to monitor equipment status and detect prediction using various sensors. Utilizing these technologies, human resources, and experience, we will develop comprehensive O&M services for offshore wind power generation facilities.

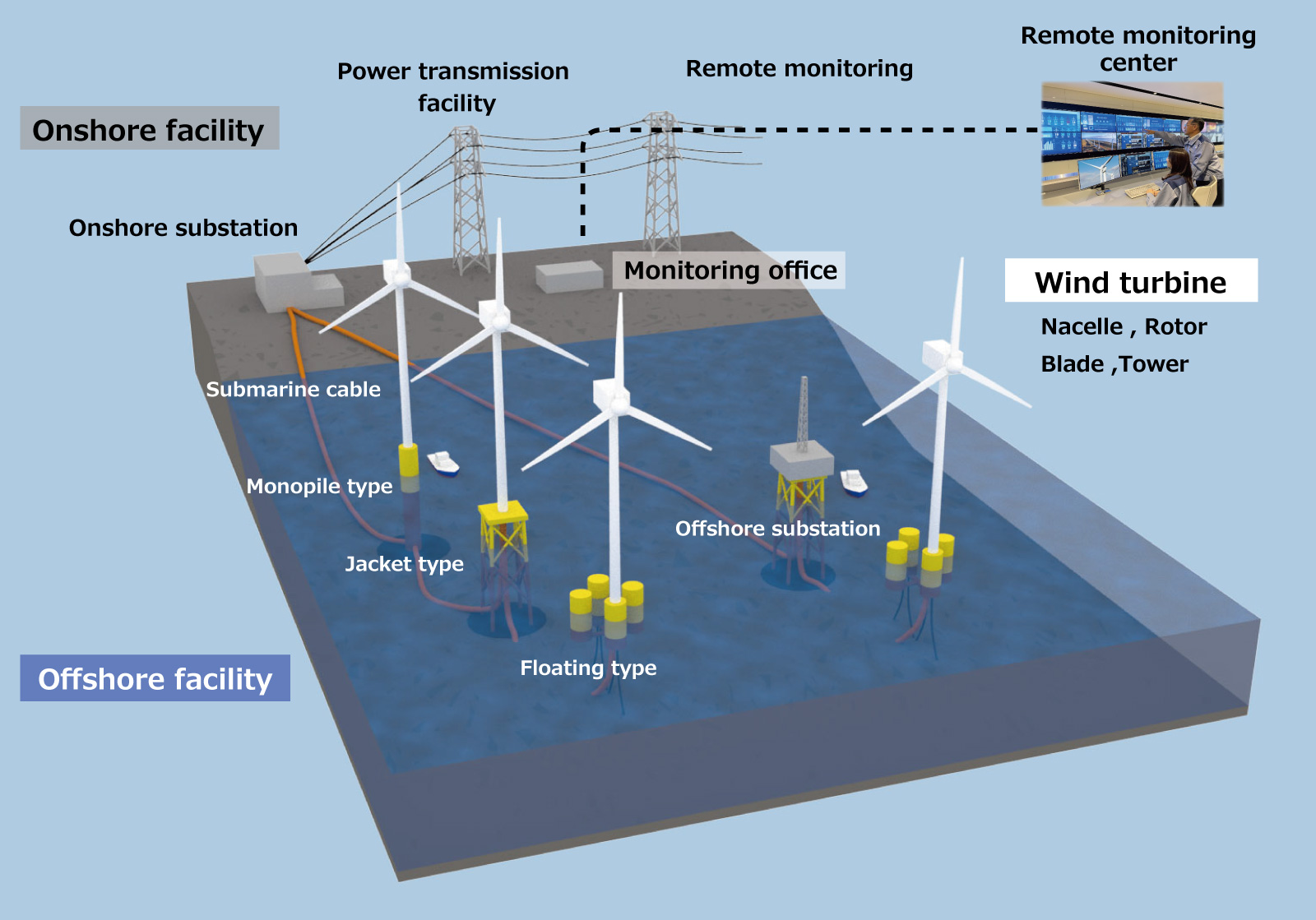

Our Service Field

Offshore facility Maintenance Service

Offshore facility maintenance services face the challenge of on-site inspections being difficult as planned due to the effects of weather and sea conditions. Therefore, we aim to carry out maintenance according to the plan by developing remote control technology and monitoring technology using sensors.

Furthermore, we are considering improving our service quality by incorporating the cooperation of specialized companies and the knowledge of our engineers in various fields.

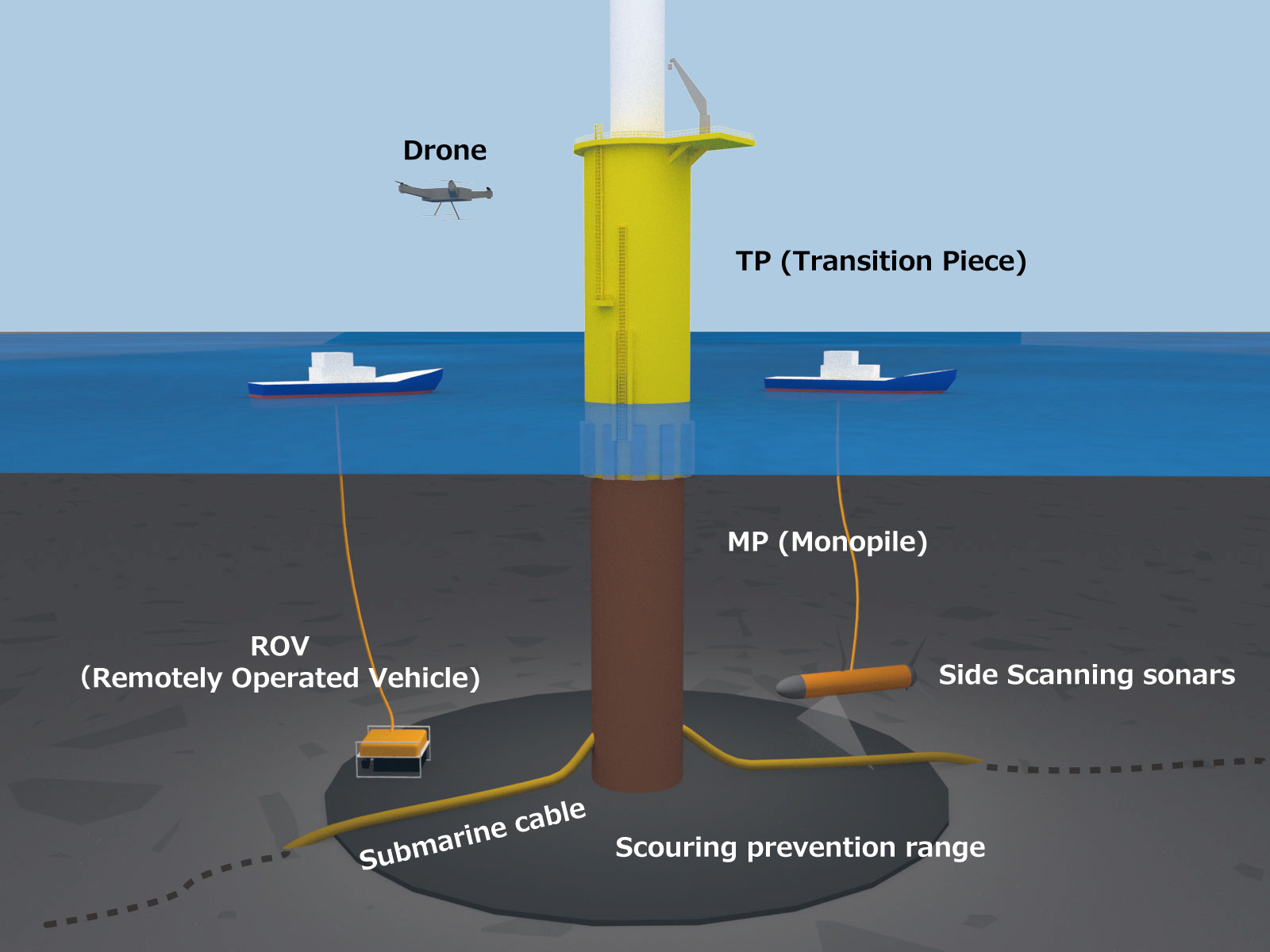

- Foundation structure Above water

- Foundation structure* Under water

- Foundation structure accessories(Secondary component)

- Submarine cable

- Seabed, Scouring prevention material

- Offshore substation

- * Foundation structure: TP (Transition Piece), MP (Monopile), JKT (Jacket), Floating type

Aiming for advanced inspection work, we will consider and utilize ROVs, drones, and other sensing technologies to realize labor saving and unmanned operations.

Inspection Image Picture

Onshore Facility Maintenance Service

In our onshore facility maintenance service, we inspect and repair onshore facilities of wind farm, and maintain and manage so that the operation of the power plant will not be hindered.

- Extra-high voltage system connection facility (switching stations, substations)

- Private line facilities (transmission lines, distribution lines)

- On-site power receiving and transforming facility

- Monitoring and control facility

- Communication facility, measuring facility

- Civil engineering (premise road), construction (administration office)

We have extensive experience in EPC and O&M for various power generation facilities, including wind farms, and can utilize our extensive know-how for offshore wind power generation facilities.

We will promote efficient O&M by utilizing the JFE Group's wide range of resources, especially by utilizing the centralized 24-hour monitoring center of the Global Remote Center (GRC).

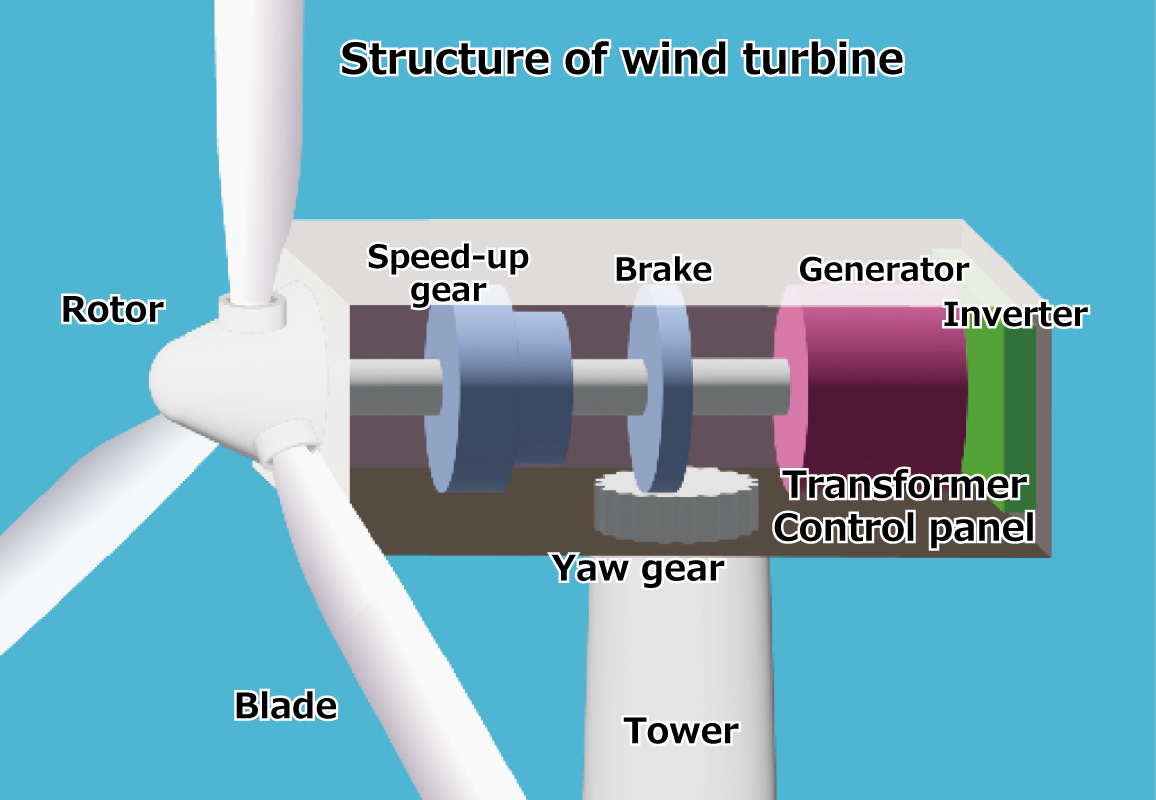

Wind Turbine Maintenance Service

We have a track record of about 20 years of experience in inspecting and repairing wind turbine parts (nacelles, rotors, blades, towers) under license agreements from European wind turbine manufacturers.

- Equipment in nacelle (Various gears, Control panels etc.)

- Equipment in rotor

- Equipment in tower (Switch gear, transformer etc.)

- Blade

Utilizing the know -how accumulated by onshore wind turbines, we will provide maintenance service to offshore wind turbines.

Replace

Blade repair

- Horonobe (750kW x 28 Units)

- Esashi (750kw x 28 Units)

- Aoyama Kogen (750kW x 20 Units)

- Kushizaki (1980kW x 1 Unit)

- Tabira (2000kW x 1 Unit) etc.

Onshore wind power generation EPC /O&M records

25 sites (131 units in total) since 1996

Representative project

- Horonobe

- Aoyama Kogen

- Kushizaki

Onshore wind power generation business investment / operation records

3 sites since 2000 (49 Units in total)

- * Only Horonobe is in operation as of 2022

Operation Service

We will participate in operating services in offshore wind farm based on the experience cultivated at the onshore wind farm (Horonobe wind farm).

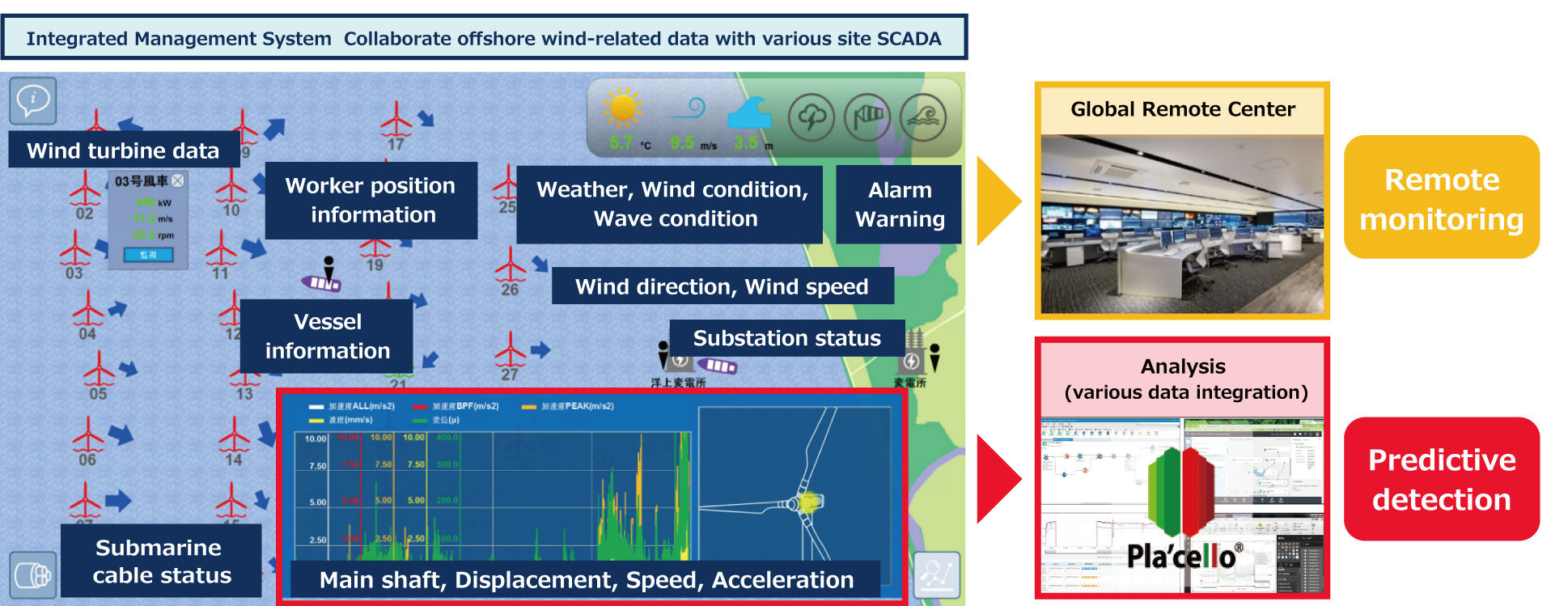

Furthermore, overall management is realized by operating an important integrated management system (ASUNAG) in operation services.

Integrated Management System (ASUNAG) image

Utilizing the remote monitoring technology (GRC: Global Remote Center), which has already been achieved at waste power generation and water-sewage treatment plants, and AI analyzing (Our analysis software: Pla’cello) the various information related to driving operations, it is possible to detect predictions such as operation monitoring management (operation, power generation, work, equipment, etc.), repair predictive diagnosis, and forecast diagnosis of replacement time.