Hybrid caissons and L-shaped caissons (for quay walls)

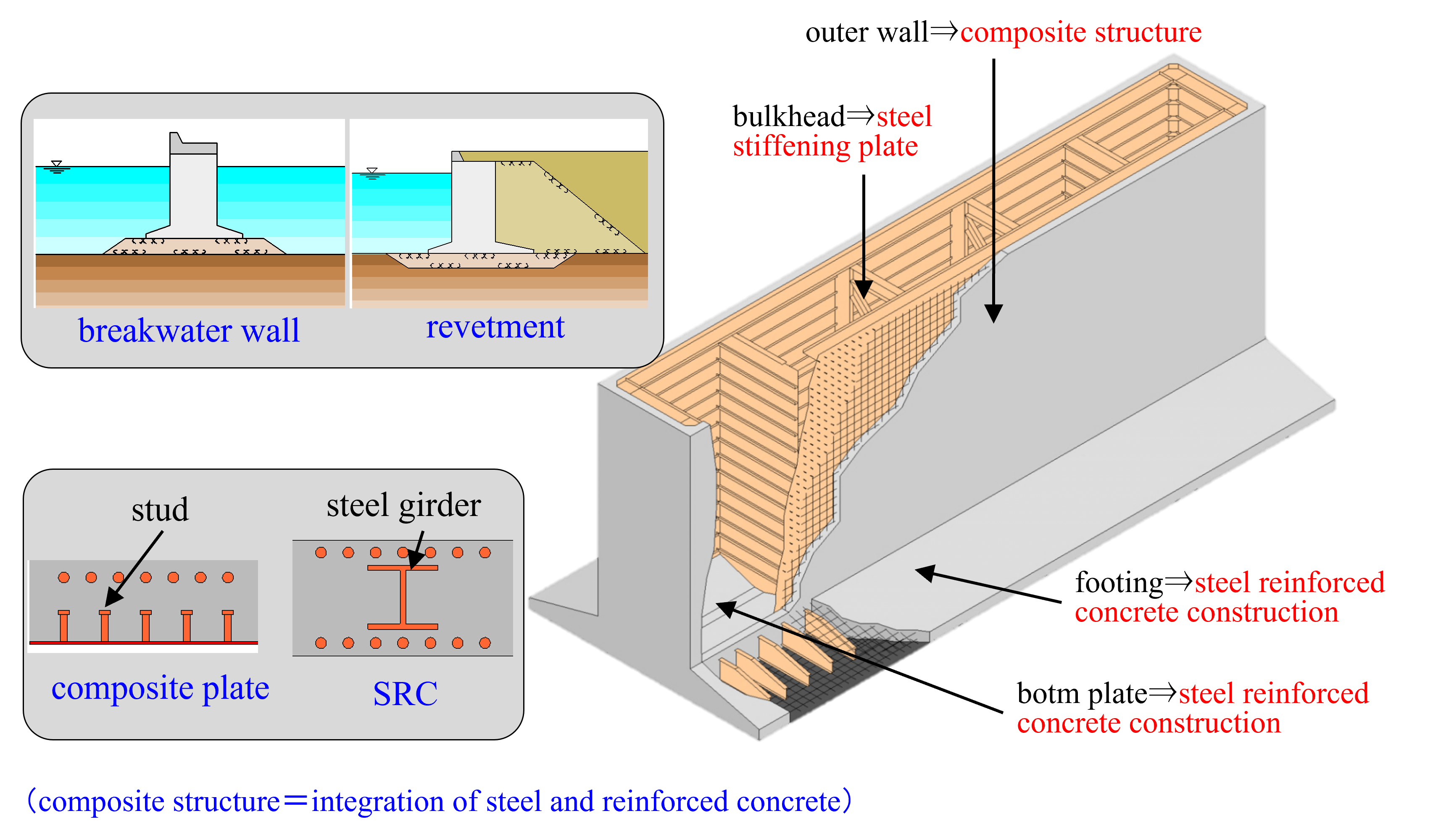

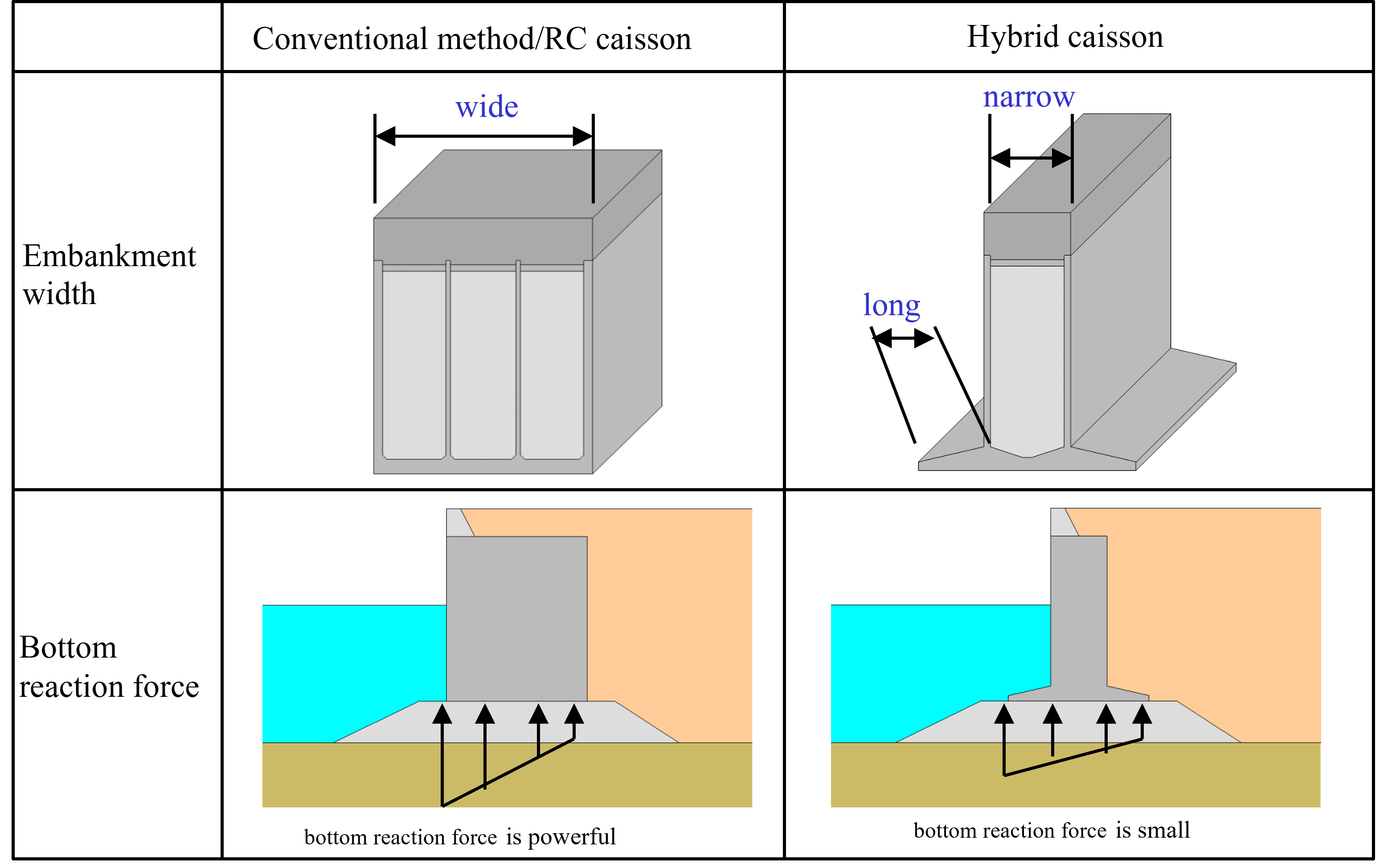

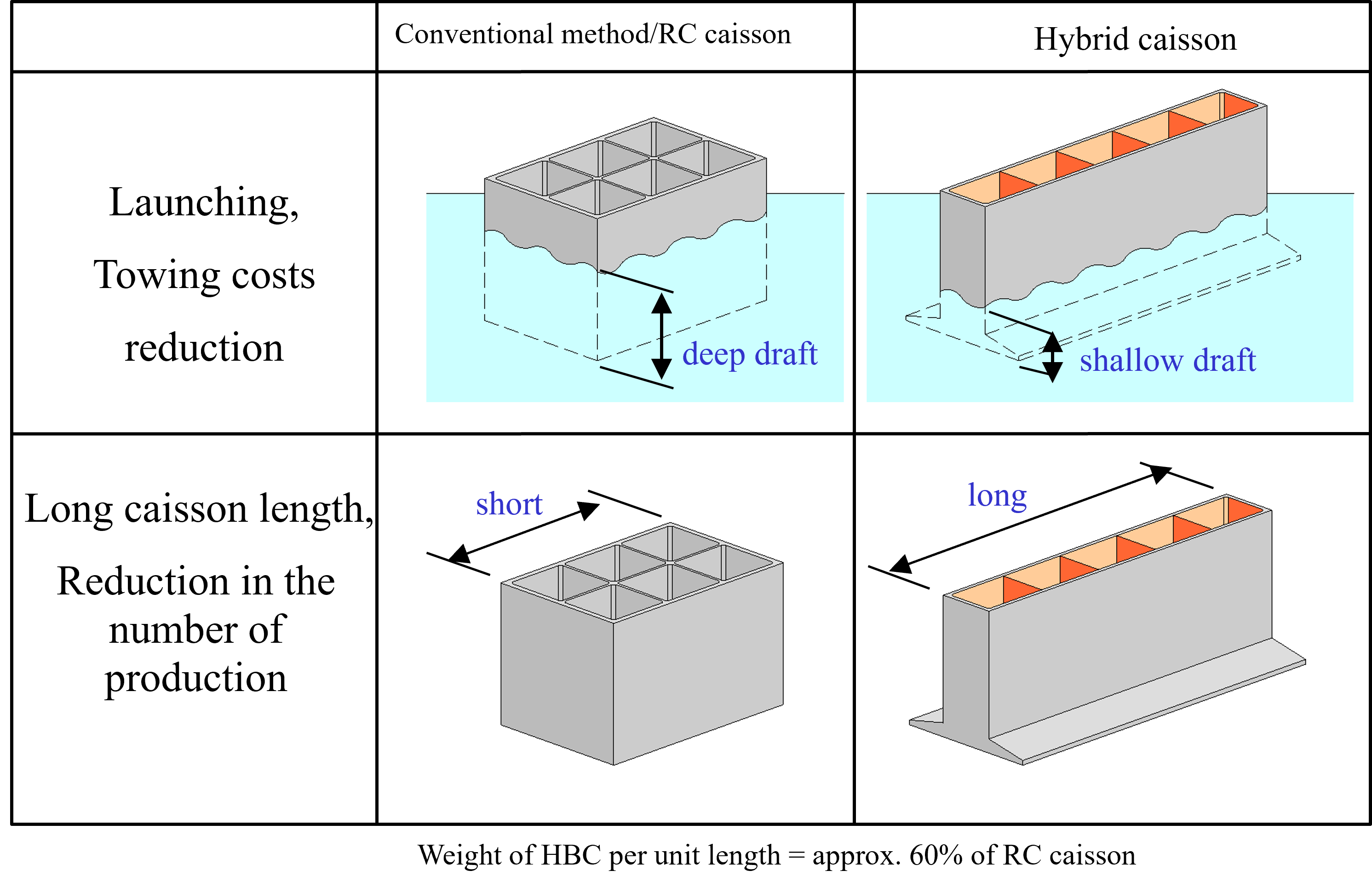

This caisson consists of a steel/concrete composite structure, which allows for longer boxlengths and footings. They can be manufactured in factories across the country and towed afloat, making them not only economical but also effective as a rapid on-site construction method.

Features of the construction method.

-

Footings can be overhung to a large extent

-

Lightweight, low draft, caissons can be lengthened

-

Labor-saving concrete work

-

Rapid on-site construction

-

Easily adaptable to various shapes

Compared with RC construction methods

Unit length weight approx. 60%.

1.5 to 2.0 times longer

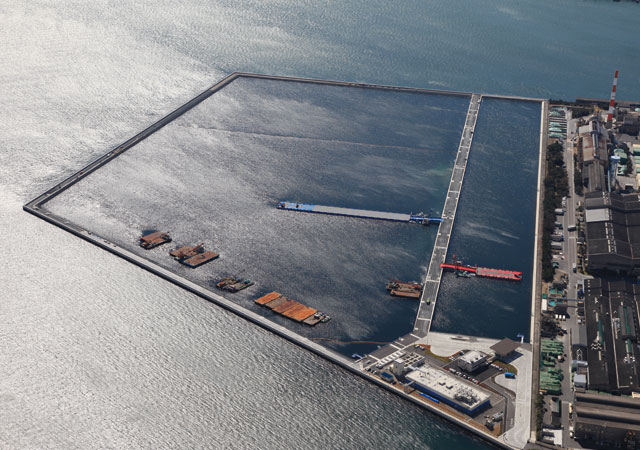

Construction examples

1.Overview

Hybrid caissons are highly economical and easy-to-construct caissons that takes advantage of the benefits of composite structure.

2.Features

Feature 1 : Footings can be extended significantly

Feature 2 : Lightweight, low draft, caisson can be lengthened

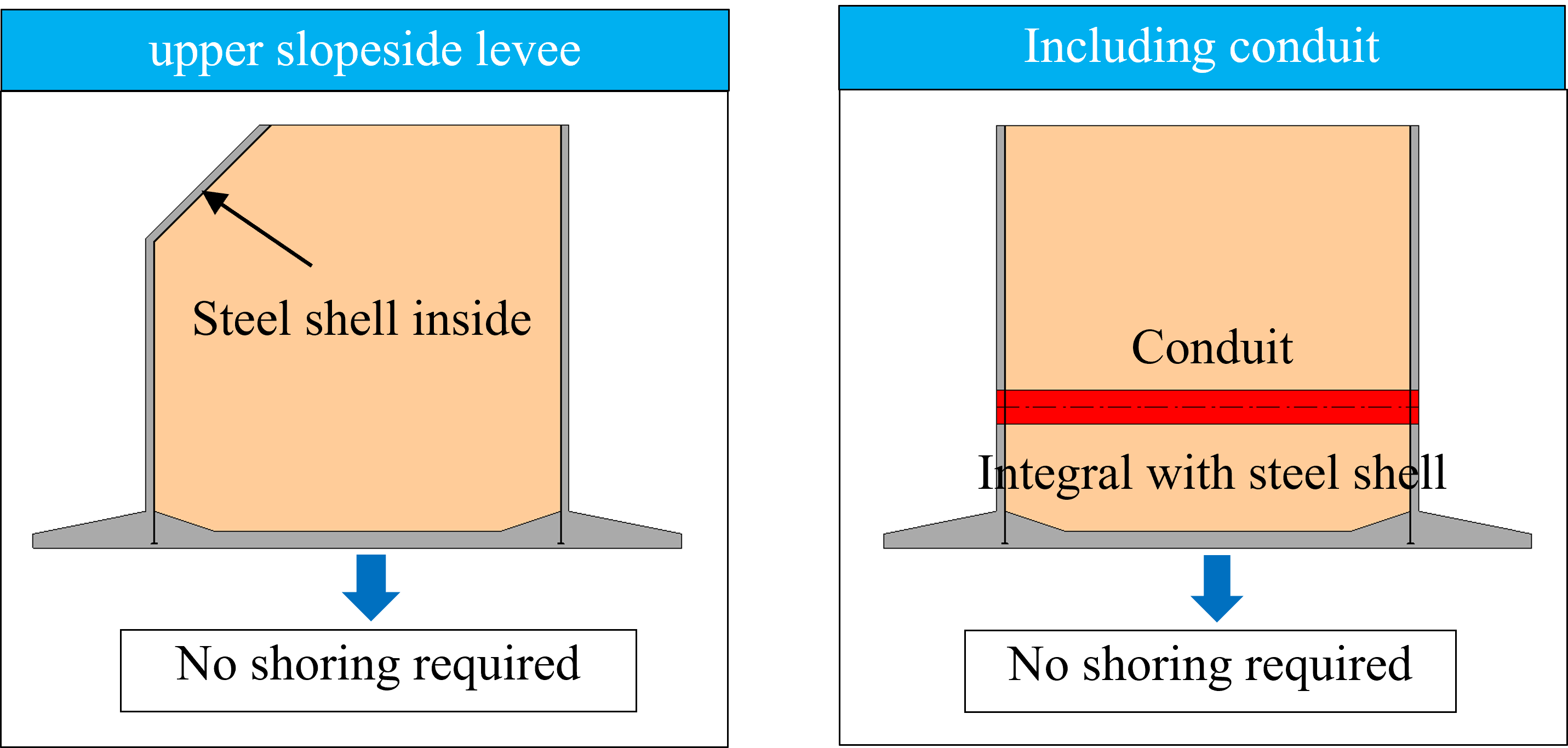

Feature 3 : Can be easily adapted to various shapes

-

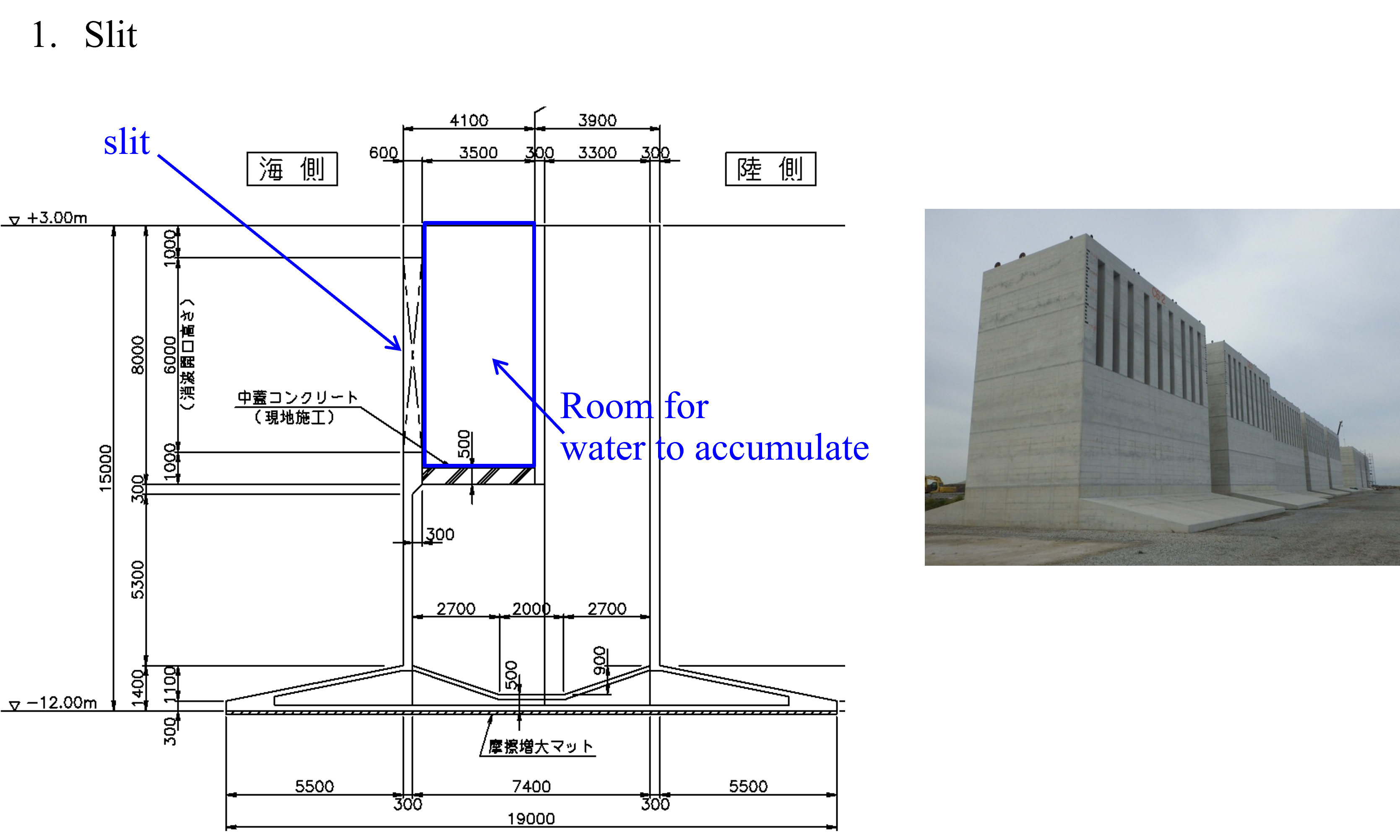

Slit

-

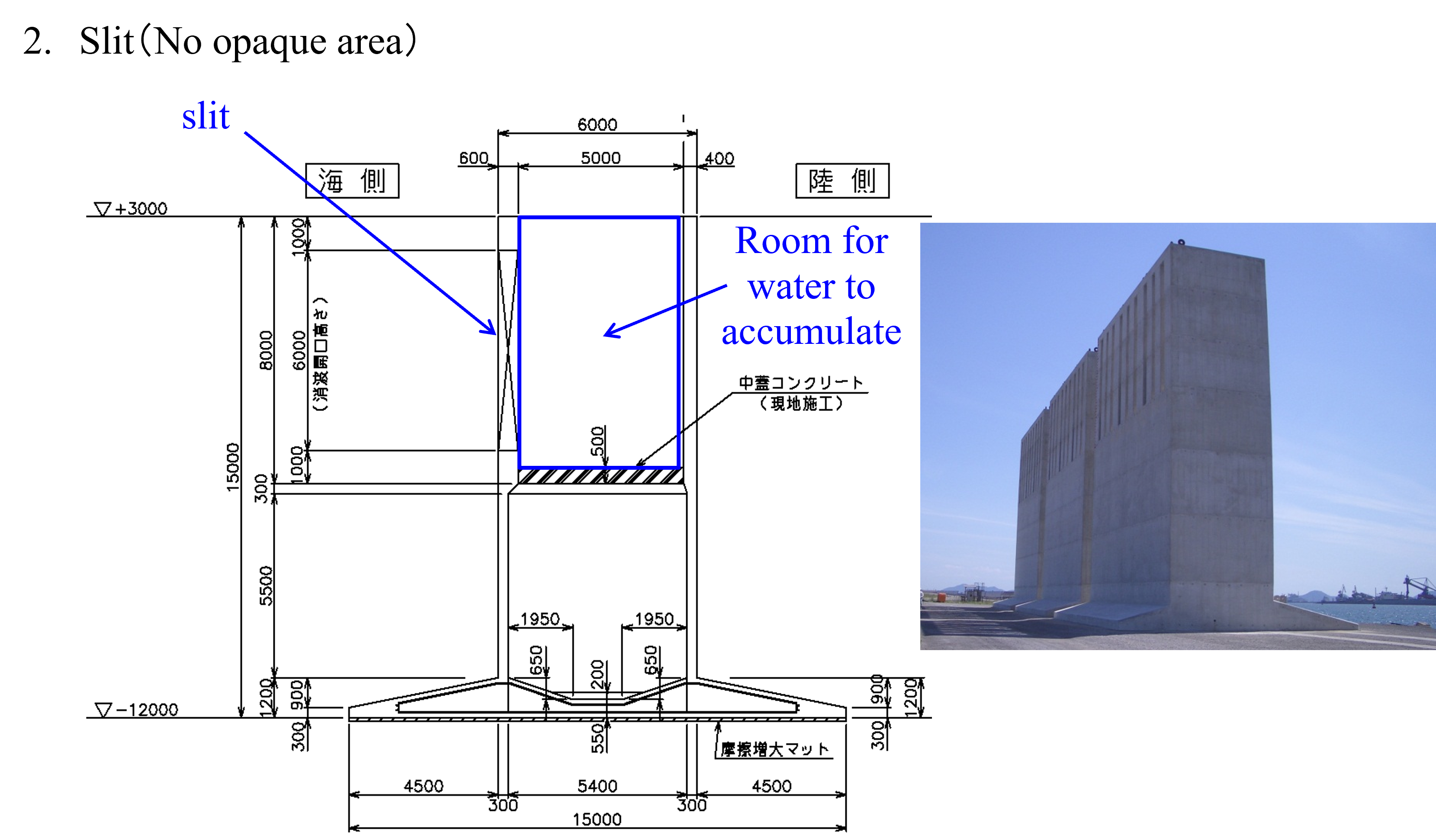

Slit (No opaque area)

-

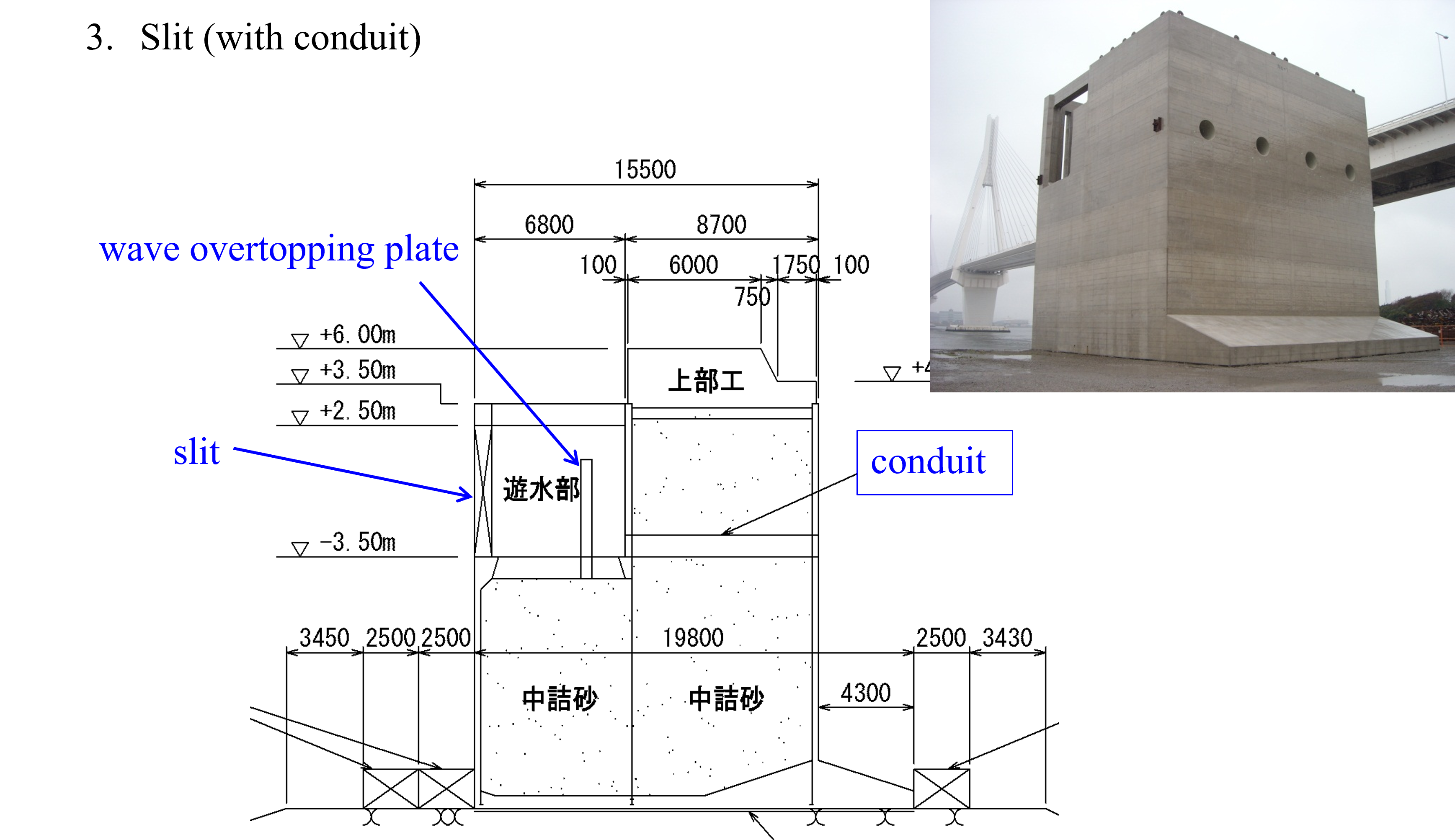

Slit (with conduit)

-

Double slit (with conduit)

-

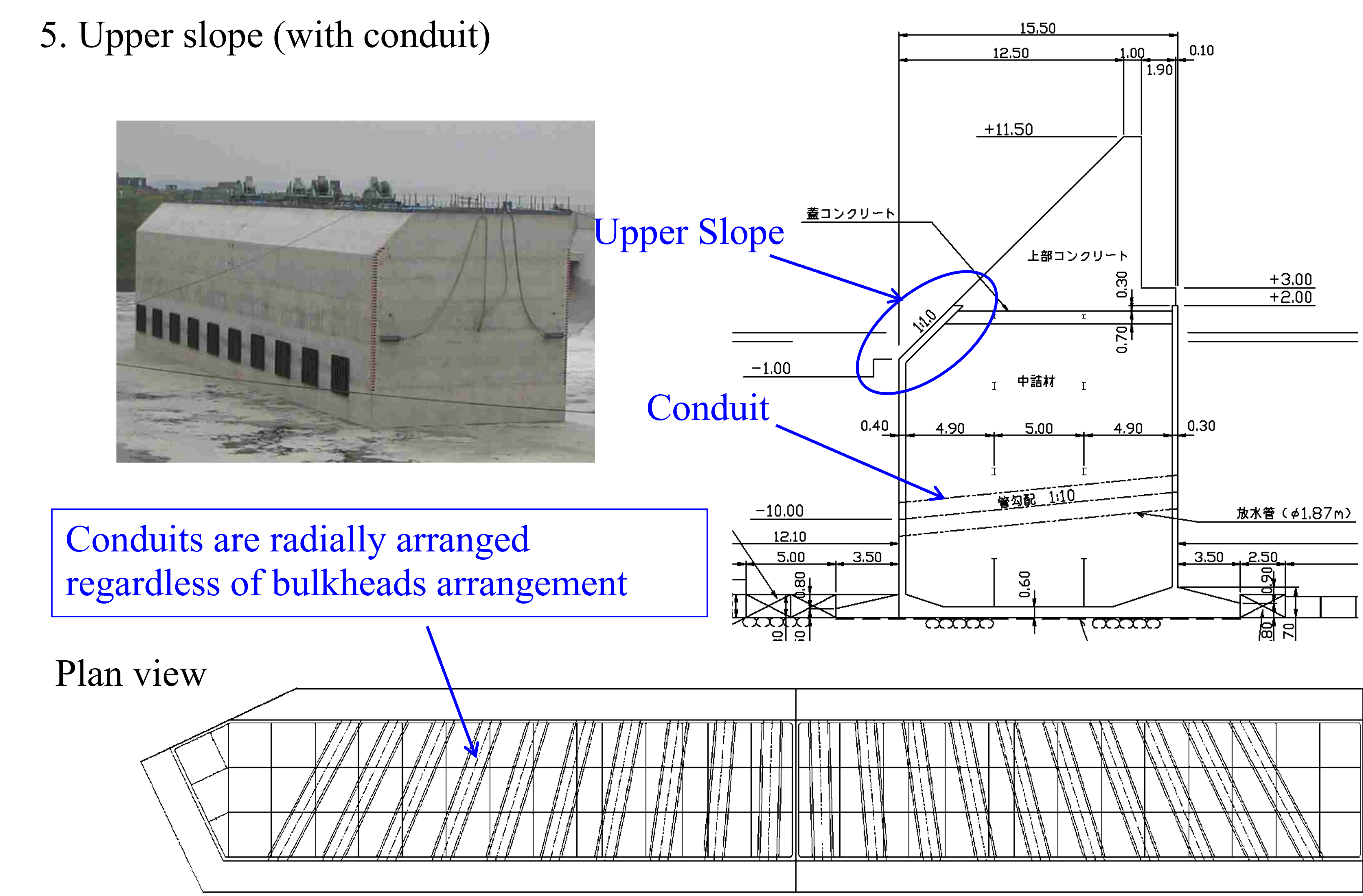

Upper slope (with conduit)

-

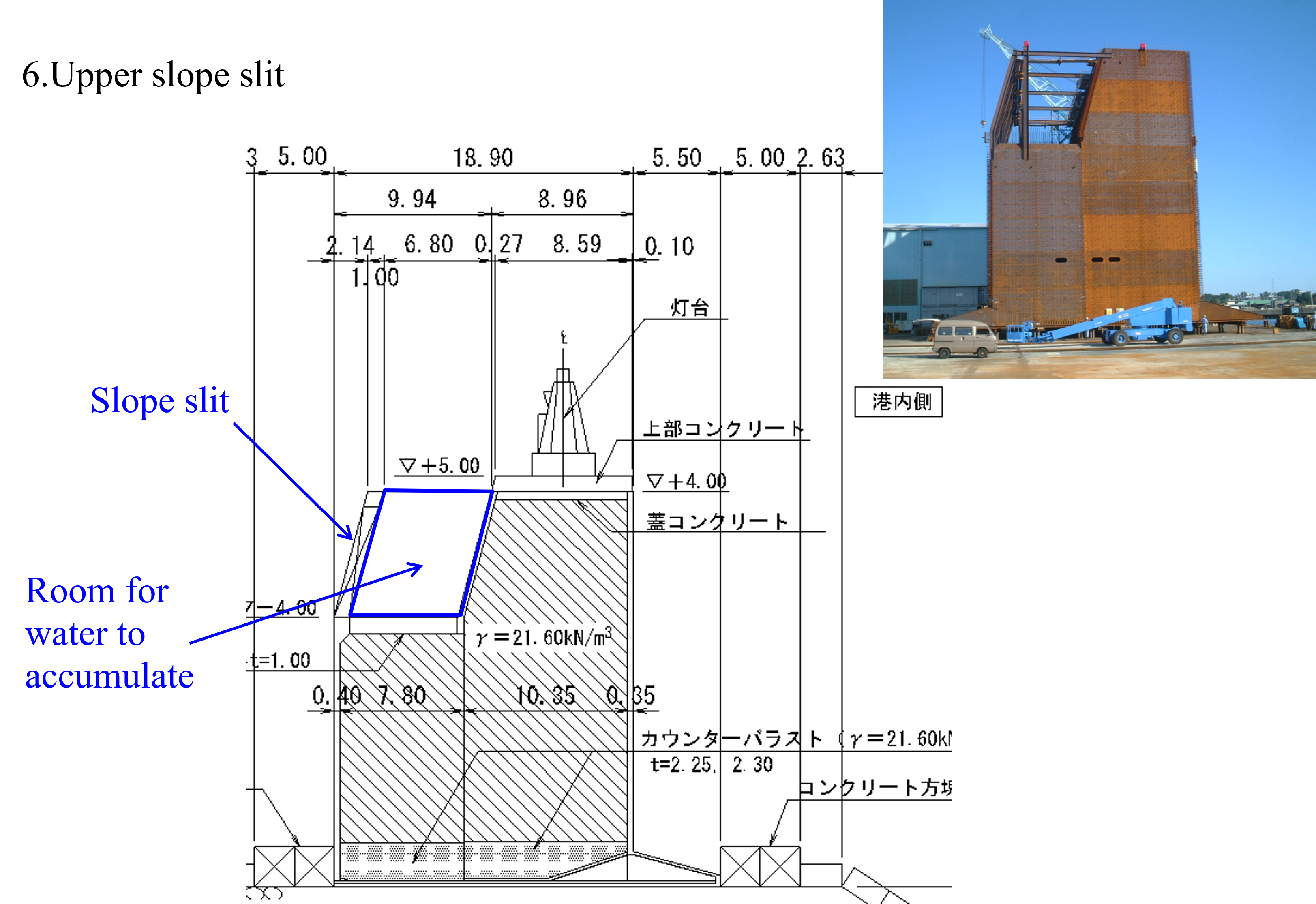

Upper slope slit

-

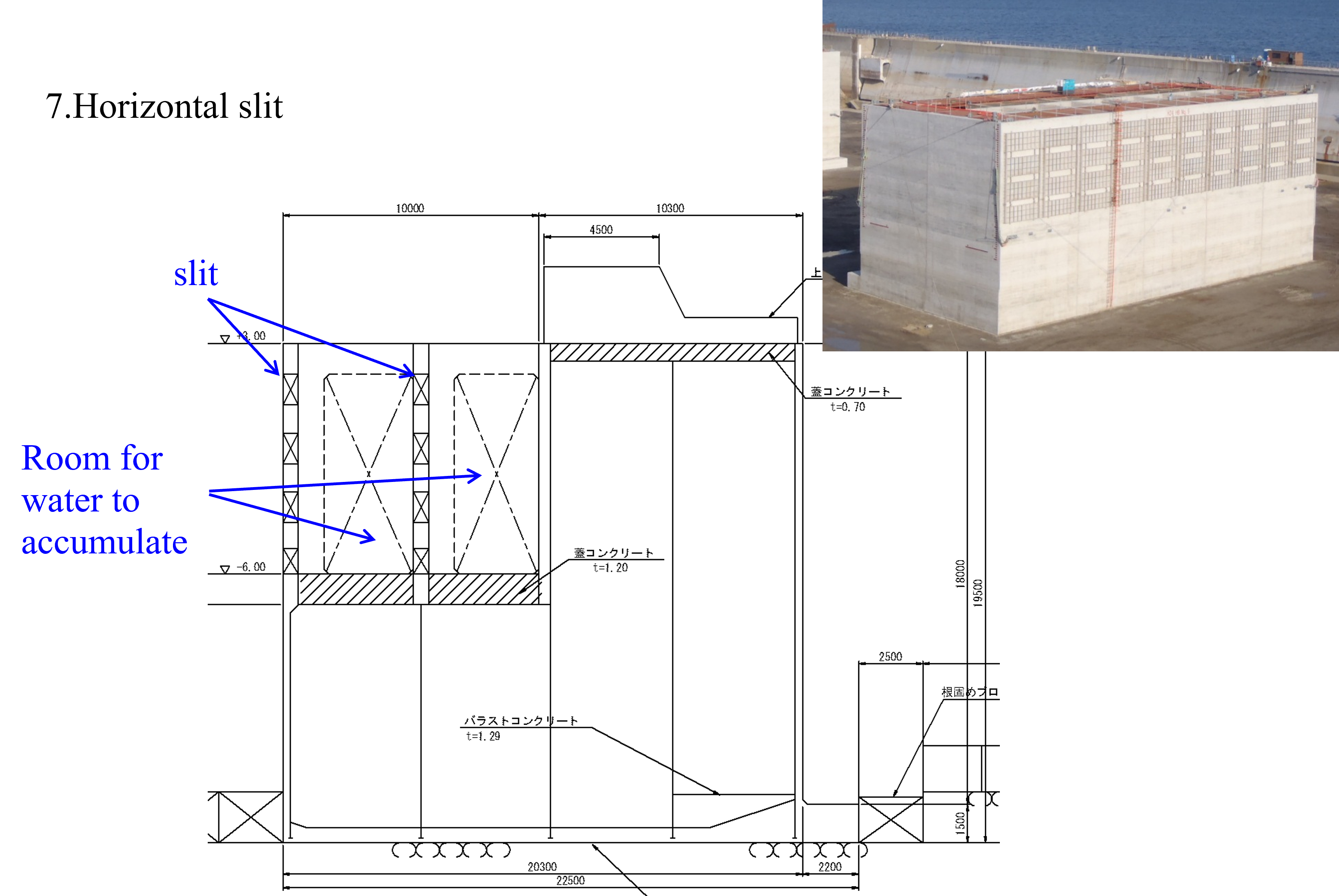

Horizontal slit

Structure examples of hybrid caissons

Construction examples

| Project name | Yokohama Port Shin-Honmoku Area Seawall (Wave Protection) Main Body Works |

|---|---|

| Client | Kanto Regional Development Bureau, Ministry of Land, Infrastructure and Transport |

| Purpose and function | Wave protection revetment |

| Year of construction | 2021 |

| Dimensions | L20*B7(16)*H19 |

| Number of units | 4 units |

| Weight | 2231 t/unit (with ballast) |

| Steel weight | 200 t/unit |

| Concrete volume | 719 m3/unit |

| Design overview | ー |

| Features and functions | ー |

| Project name | Construction of Nagoya Port Kinjo Pier Quay (-12m) in 2019 |

|---|---|

| Client | Chubu Regional Development Bureau, Ministry of Land, Infrastructure, Transport and Tourism |

| Purpose and function | Quay (-12m) |

| Year of construction | 2020 |

| Dimensions | L35.0*B7.2(17.2)*H16.2 |

| Number of units | 2 units |

| Weight | 2770 t/box |

| Steel weight | 363 t/unit |

| Concrete volume | 940.6 m3/box |

| Design overview | Design depth (-12.6 m) |

| Features and functions | ー |

| Project name | New Honmoku Wharf construction work (No. 8, caisson steel shell fabrication work) |

|---|---|

| Client | Yokohama City |

| Purpose and function | Seawall |

| Year of construction | 2020 |

| Dimensions | L25.0*B8.0 (10.5)* H13.5 |

| Number of units | 5 units |

| Weight | 1947 t/unit |

| Steel weight | 125 t/unit |

| Concrete volume | ー |

| Design overview | Design depth (-10 m) |

| Features and functions | ー |

| Project name | Sluice gate lower steel shell fabrication work |

|---|---|

| Client | Ibaraki Prefecture |

| Purpose and function | Lower part of sluice gate |

| Year of construction | 2018 |

| Dimensions | L27.5*W29.5*H14.5 |

| Number of units | 1 unit |

| Weight | ー |

| Steel weight | 691 t/unit |

| Concrete volume | ー |

| Design overview | Sluice gate bed height (-6.0 m)/design seismic intensity 2.0 |

| Features and functions | Hybrid pier (sluice gate lower foundation) |

| Project name | Ash dumping site revetment on the north side of the front of the Kinuura 1 site |

|---|---|

| Client | JERA Co., Inc. |

| Purpose and function | Waste revetment |

| Year of construction | 2016~2018 |

| Dimensions | L90.0*B19.0*H16.2 etc. |

| Number of units | 14 units |

| Weight | 7900 t/unit, etc. |

| Steel weight | 1175 t/unit |

| Concrete volume | ー |

| Design overview | Design depth (-13 m) / Design seismic intensity 0.19 |

| Features and functions | ー |

| Project name | Ukishima 2nd phase waste landfill C revetment caisson fabrication works |

|---|---|

| Client | Kawasaki City |

| Purpose and function | Wave dissipation and waste landfill perimeter revetment |

| Year of construction | 2013 |

| Dimensions | Length 20.0 x Width 8.0/16.0 x Height 15.0 m |

| Number of units | 24 units |

| Weight | 1,868 t/unit |

| Steel weight | 62~130 t/unit |

| Concrete volume | 512-563 m3/unit |

| Design overview | Installation water depth -12.0 m, design seismic intensity 0.22 |

| Features and functions | Long footing (overhang length 5.5 m) |

| Project name | Kamaishi Harbour Mouth Area Bay Mouth Breakwater (Disaster Recovery) Main body of work |

|---|---|

| Client | Ministry of Land, Infrastructure and Transport Tohoku Regional Development Bureau |

| Purpose and function | Breakwater at the mouth of the bay (restoration) |

| Year of construction | 2012 |

| Dimensions | Length 50.0*Width20.3/22.5*Height 19.5 m |

| Number of units | 2 units |

| Weight | 7,603 t/unit |

| Steel weight | 865 t/unit |

| Concrete volume | 2,474 m3/unit |

| Design overview | Installation depth -16.5 m, design wave height (H1/3) 7.3 m, design seismic intensity 0.20 |

| Features and functions | Marine dock fabrication (Draft 7.2 m) |

| Project name | Gamagori Quay Construction for the Port of Mikawa Rehabilitation Project |

|---|---|

| Client | Aichi Prefecture |

| Purpose and function | Wave Absorbing Quay (-11 m) |

| Year of construction | 2011 |

| Dimensions | Length 50.0*Width 14.7*Height 13.5 m |

| Number of units | 3 units |

| Weight | 3,878 t/unit |

| Steel weight | 310 t/unit |

| Concrete volume | 1,145 m3/unit |

| Design overview | Installation depth -11.5 m, design seismic intensity 0.17 |

| Features and functions | Long caisson, offshore dock fabrication (draft 7.8 m) |

| Project name | Port of Kinuura No. 3 waste final disposal site development project revetment works |

|---|---|

| Client | Aichi Rinkai Environmental Improvement Centre |

| Purpose and function | Seawall within waste landfill |

| Year of construction | 2010 |

| Dimensions | Length 90.0*Width 15.0*Height 17.5 m |

| Number of units | 9 units |

| Weight | 6,067 t/unit |

| Steel weight | 944~1061 t/unit |

| Concrete volume | 1,809~1,942 m3/unit |

| Design overview | Installation depth -14.0 m, design seismic intensity 0.12 |

| Features and functions | Long caisson, offshore dock fabrication (draft 5.0 m) |

| Project name | Tsuruga Power Station Units 3 and 4 Breakwaters, Seawall Installation and Other Works |

|---|---|

| Client | The Japan Atomic Power Company |

| Purpose and function | Upper sloping discharge embankment |

| Year of construction | 2007 |

| Dimensions | Length 62.4*Width 15.5*Height 17.5 m |

| Number of units | 2 units |

| Weight | 7,990 t/unit |

| Steel weight | 1177~1255 t/unit |

| Concrete volume | 2,364~2,492 m3/unit |

| Design overview | Installation depth -15.5 m, design wave height (H1/3) 9.78 m |

| Features and functions | With water discharge pipe (φ2300), offshore dock fabrication (draft7.0 m) |