First in Japan! Development of the Umbrella Deck, a new expansion scaffold

A 75%※1 reduction in the number of workers necessary! Contributing to the reduction of necessary labor, the shortening of the time necessary to accomplish the work, and improving safety

JFE Engineering and Nisso Industries have developed the Umbrella Deck, a new expansion scaffold that is expected to be used widely in the construction industry.

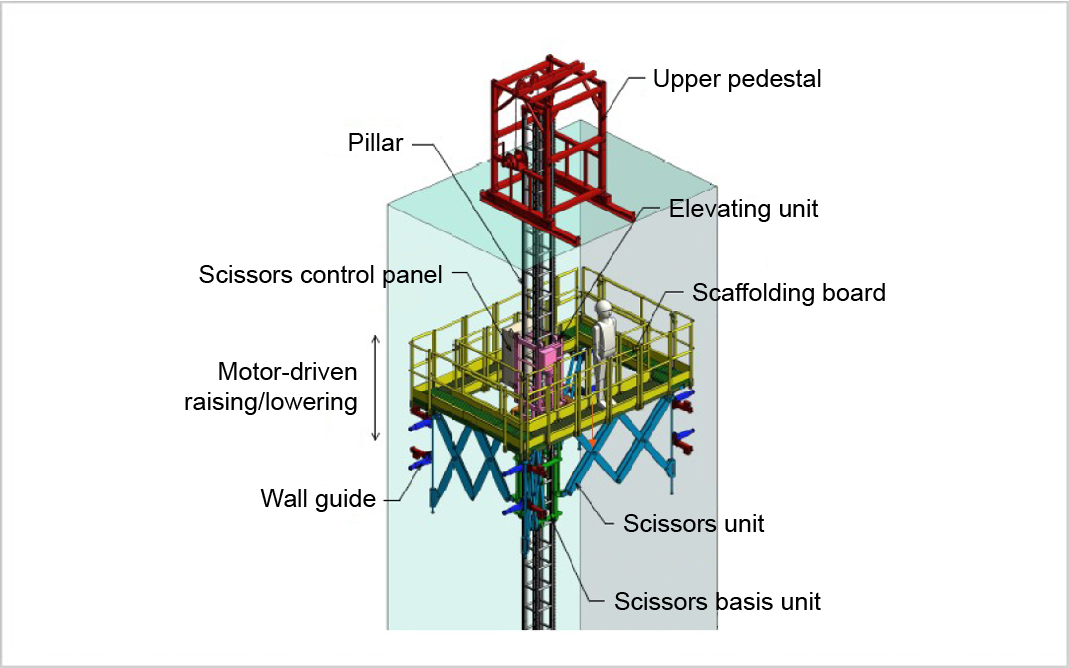

The new scaffold consists of small parts, which are carried into buildings using openings on the roof of the structure and then assembled. The scaffold is raised and lowered electrically. This product can be set up more safely and quickly than other solutions.

Conventionally, tube and coupler scaffolding is set up for maintenance work at Waste-to-energy (WtE) plants and similar facilities because maintenance involves a lot of work in high places. Setting up tube and coupler scaffolding involves many workers handling long pipes and other parts by in small spaces, which means there is a high risk of accidents. In addition, the quality of assembled scaffold is not equal. It varies according to the skills of the workers. This also causes variations in the level of safety. Additionally, it takes a long time for the scaffolding to be assembled and disassembled, which has been a cause of prolonged shutdowns at facilities. To solve these issues, the two companies have developed the new expansion scaffolding, the first of its kind in Japan. The new scaffold can be quickly set up by a small number of workers, and it can be used more safely with greater peace of mind.

In a demonstration test conducted using Umbrella Deck, scaffolding work inside a boiler, which previously required four days and eight workers, was completed in two days by four workers. This is a 75% reduction of labor and a two-day reduction of the work period. The scaffold is a system product to be assembled. Therefore, it is always safe, regardless of the skill level of the workers who set it up.

Presently, preparations are under way to commercialize the Umbrella Deck. Moving forward, the companies will expand its applications to WtE plants, a range of boilers, storage tanks including silos and plant equipment and structure construction and maintenance sites.

By introducing the new scaffold, the two companies will proactively help increase safety, reduce the labor necessary, and improve productivity on construction sites.

Product specifications

- Name

- 「Umbrella Deck」※2

- Features

- Small parts are carried into the building via an opening on roof of the structure. The extendable scaffold can be set up in a short period.

- Benefits

- 75% reduction of the workers necessary, setup period that is two days shorter ※3 and a system product that ensures uniform assembly quality

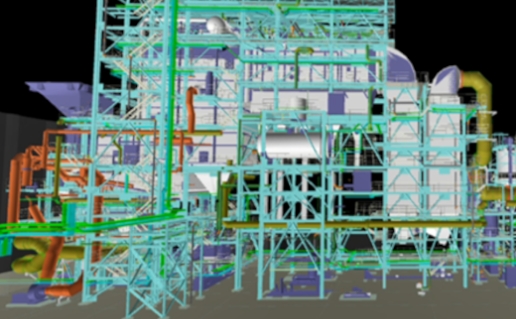

Umbrella Deck scaffold set up in an incineration plant boiler (Kumamoto City Seibu Incineration Plant)

Scaffold structure

※1,※3:Results of a demonstration test conducted by JFE Engineering /※2:Patent pending

A video introducing the product

Other cases

-

For unmanned operation of environmental plants

Waste-to-energy (WtE) plants used to be operated manually by skilled operators who relied on their ...

View More -

Automatic AI-based Inspection of Bridge Reinforcement

In bridge construction, placement inspection to confirm that the steel bars have been installed as designed is...

View More -

Detecting signs of operational failure at biomass energy plants

Biomass power generation seeks to achieve high output with stable, efficient power generation regardless...

View More -

Dam Optimal Operation System

JFE Engineering and Hokuriku Electric Power Company are jointly developing the Dam Optimal Operation System ...

View More -

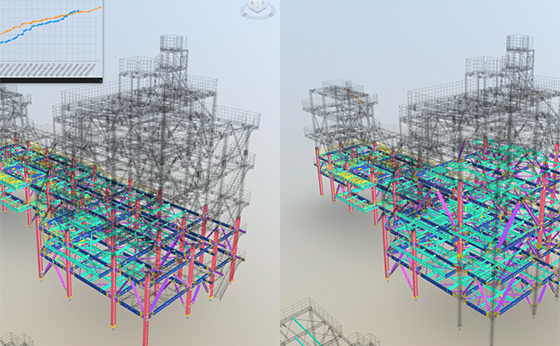

Utilization of 3D

At construction sites, it is important to manage the arrival of parts and the progress of construction...

View More -

Optimizing plant operations using digital twin

JFE Engineering is using a digital twin to make plant operation more efficient. Biogas plants use food ...

View More -

Bolt tightness inspection system using AI image recognition technology

Steel bridges are constructed by connecting 10-meter-long segments with high-strength bolts. Normally...

View More -

Development of construction robots for plant construction sites

JFE Engineering, Okaya & Co., Ltd., and AKTIO Corporation have jointly developed three models of construction robot for use on plant construction sites...

View More