JFE Stoker Grate Incineration Technology

Making the most of waste to generate energy

Our proprietary high-efficiency combustion system achieves significant reduction of waste volume while recovering high levels of waste heat. The development of our energy recovery technology is based on our extensive experience in the construction and development of more than 170 facilities in Japan and abroad. Our technologies have received high praise from our customers worldwide.

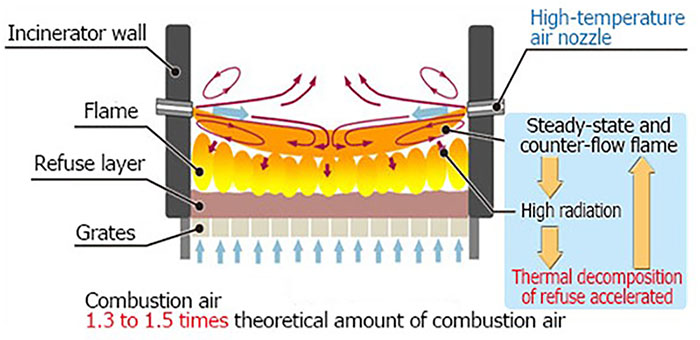

High-Temperature Air Combustion Technology

Achieving stable combustion, low generation of CO and NOx

JFE successfully developed a first-of-its-kind High-Temperature Air Combustion Technology for waste incineration. Combined with exhaust gas recirculation, JFE’s system can achieve stable Low Excess Air Ratio combustion. This technology was the recipient of the Technology Award from the Combustion Society of Japan.

Stable Low Excess Air Ratio combustion suppresses the generation of harmful substances such as carbon monoxide (CO) and nitrogen oxides (NOx) in the exhaust gas, and further reduces heat loss by decreasing the exhaust gas volume, thereby improving waste heat recovery efficiency.

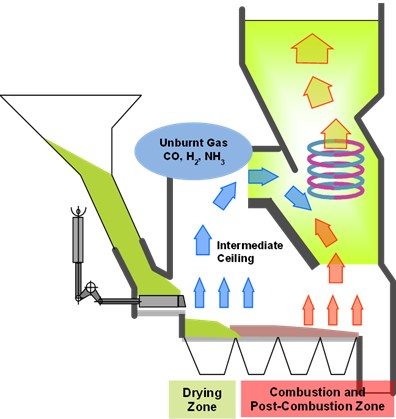

Two-way Flue Gas Combustion System

Achieves complete combustion of unburned carbon monoxide (CO), suppression of dioxins and low NOx emission

The unburned and combustion gases are separated by an intermediate ceiling in the combustion chamber and are made to collide in the gas mixing chamber. This gas turbulence achieves complete combustion of unburned gas and the reduction in the concentration of dioxins, carbon monoxide, and nitrogen oxides in the exhaust gas.

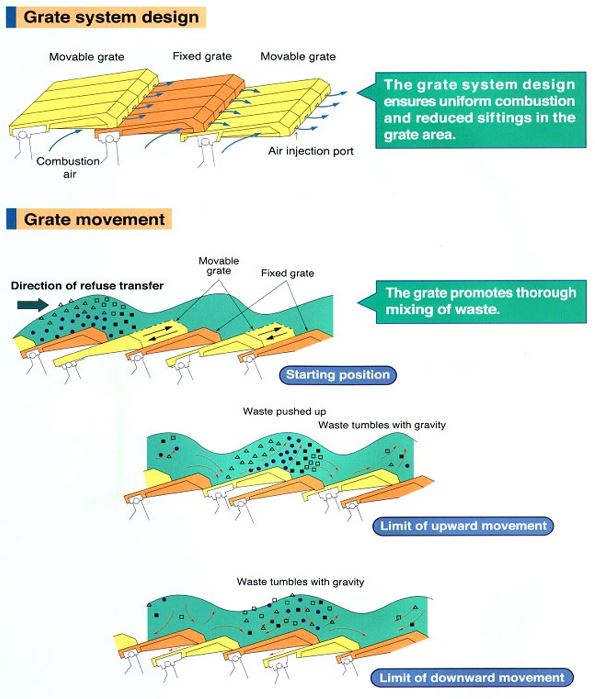

Hyper Grate

Highly stable combustion with excellent waste mixing capability

The grate system is composed of horizontal rows of moving and fixed grates alternatively arranged along the furnace.

Each grate is mounted facing upward in the direction of the waste flow so that the moving grates move back and forth over the fixed grates to effectively mix and push the waste forward. Combustion air is injected through vents in the grates which are expertly engineered to reduce the siftings in the grate area.

Reference Plants

| Name | Funabashi City Nambu Incineration Plant |

|---|---|

| Capacity | Stoker-type incinerator 339 tons/day (113 tons/day x 3 furnaces) |

| Completion | March 2020 |

| Name | Higashi-Osaka Urban Cleaning Facilities Association Plant No. 5 |

|---|---|

| Capacity |

Stoker-type incinerator 400t/day (200t/day x 2 furnaces) Bulky waste treatment facility 50t/day |

| Completion | Completion: April 2017 |

| Name | Kumamoto City Seibu Incineration Plant |

|---|---|

| Capacity | Stoker-type incinerator 280 t/day (140 t/day x 2 furnaces) |

| Completion | February 2016 |

| Name | Nerima Incineration Plant |

|---|---|

| Capacity | Stoker-type incinerator 500t/day (250t/day x 2 furnaces) |

| Completion | November 2015 |