Design and construction of steel/concrete composite deck slab bridges

Overview of the technology

River Bridges (KCSB) are steel/concrete composite deck slab bridges developed by JFE Engineering. Combining the advantages of steel and concrete, they can be constructed to a low structural height that could never be realized with steel bridges and PC bridges. They are simple in structure, consisting mainly of shape steel, and outperform other types of bridges in terms of onsite workability.

For the quarter century since 1981, when the first River Bridge (KCSB) was constructed, our river bridges have been adopted for a wide variety of single-span bridges, from the replacement of old bridges as river improvement work to the new construction of bridges in urban areas, road bridges, overbridges, and pedestrian bridges. To date, we have constructed about 420 bridges all over Japan, from Hokkaido to Kyushu to Okinawa.

River Bridges can be constructed with effective spans ranging from about 10 to 40 meters and skew angles of 45 degrees or more and can be adapted to changes in structural height according to their longitudinal alignment. They are now compatible with continuous girders, expanding their range of applications. River Bridges (KCSB) have a greater potential to meet social needs, labor saving and speedup of onsite construction works and the minimization of life cycle costs.

Features

1.Low structural height

From among all structural types, River Bridges can achieve the lowest structural height.

2.Rapid construction

The construction weight of River Bridges is far lighter than that of concrete-based bridges, so heavy equipment can be downsized. In addition, formwork and scaffolding are no longer necessary as the bottom panels function as deck slab formwork, resulting in the reduction of the construction work period.

3.Minimization of LCC

The RC deck slabs, which are of a highly durable structure, are almost maintenance-free and also contribute to the minimization of life cycle costs.

4.Designability

River Bridges can offer not only a slender appearance thanks to their low structural height but also impressive landscaping design.

Features of the structure

Overview

1.Low structural height

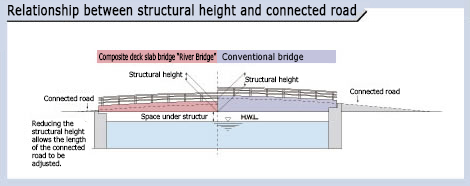

The core feature of River Bridges (KCSB) is their low structural height. The effective span-structural height ratio is 1/30 to 1/42, and the height of girder ends can be reduced to a minimal 30 cm.

When the gap between the estimated high water level and the planned road height in an urban area is inadequate, as is often the case, River Bridges can offer a sufficient geometric line road form. The extension of the access road can also be shortened by reducing the structural height so that it will be easier to secure the necessary surrounding land.

2.Deck slabs with high durability

The results of moving wheel load driving tests prove that the RC deck slabs of River Bridges are equal to composite deck slabs in fatigue durability. River Bridges can serve for 100 years thanks to the fatigue durability of these deck slabs and of the steel members.

3.Weight of steel materials

The core feature of River Bridges (KCSB) is their low structural height. The effective span-structural height ratio is 1/30 to 1/42, and the height of girder ends can be reduced to up to about 30 cm.

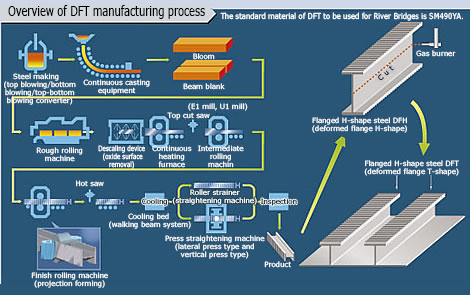

4.DFT is used for the main girders

Shear connectors play the important role of letting the steel panels and concrete behave together in a composite structure. River Bridges (KCSB) use DFT as shear connectors for the main girders. DFT (Deformed Flange T-shape) is the T-shaped steel produced by cutting half H-shaped steel (Deformed Flange H-shape) with projected lines, which are formed on the external surface of the flange at the stage of rolling. The height of the main girders can be adjusted via the height of the extended web.

Details

1.Standard cross section

2.Details of the structure

3.New technology (Hyper Bridge)

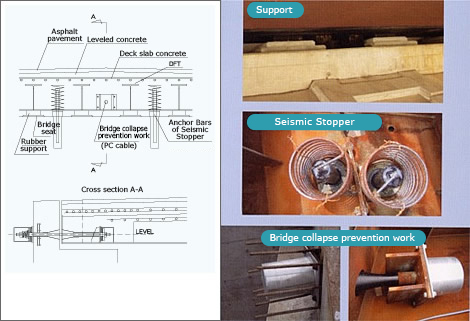

Hyper Bridges are composite rigid-frame bridges made up of a River Bridge with steel-concrete composite structure bridge piers (REED method bridge piers) rigidly connected thereto.

-

Reduced construction work period: Since the bridge piers (REED method bridge piers) and the joints are prefabricated, construction work can be performed rapidly.

-

Lower structural height: The structural height can be minimized by the superstructure design (River Bridges).

-

Improved earthquake resistance: The rigid-frame structure gives Hyper Bridges higher earthquake resistance.

-

Reduced maintenance costs: Maintenance costs are reduced as the supports do not require maintenance.

-

Better landscape: A superstructure with fewer concave and convex portions presents a better landscape.

Design

Basic concept of design

1.Applicable standard

The basic concept of design conforms to Specifications for Highway Bridges Parts I to V (March 2002). The “Design and Construction Work Guidelines for Composite Deck Slab Bridges (draft): Composite Deck Slab Bridge Research Center” applies to matters related to composite deck slab bridges.

2.Analysis method

In principle, design section force is calculated by analyzing the grids formed by the main girders consisting of bottom slabs for which the effective width is taken into account, projected T-shaped steels (DFT) and the extended webs. Simplified analysis can also be applied to road bridges, such as right bridges or pedestrian bridges.

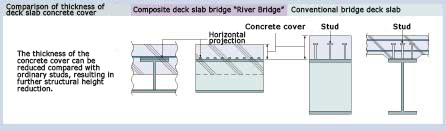

Steel/concrete composite structure

The pre-composition dead load is resisted by the cross section of steel, and the post-composition dead load and the live load are resisted by the composite cross section. Compared with stud dowels, etc. for ordinary composite girders, the steel/concrete composite structure is inexpensive and lower in structural height, as its integration depends on the adhesive force of projections of DFT and concrete.

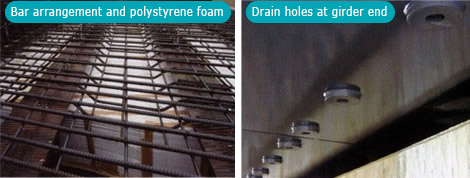

3.Two types of structure: solid type and hollow type

The solid type is the standard structure for bridges with an effective span of up to about 20 meters, whereas the hollow type is for those with a longer span.

- Polystyrene foam is generally used for embedded formwork.

- Hollow type bridges require coating on deck slab reinforcing bars and the internal surface of the hollow area.

4.Shape of the steel girders

The standard shape of the steel girders is described below.

- The DFT members are placed straight and parallel to one another at equal intervals.

- The steel girders are level with one another in the direction perpendicular to the center line of the structure, and the crossfall of the road surface is leveled and adjusted with concrete.

5.Expansive concrete

To prevent cracking attributable to drying shrinkage, expansive concrete is used.

6.Steel material requiring minimum maintenance

For the purpose of saving labor required for future maintenance, weather-resistant steel (bare type, stabilizing-treated type, etc.) is used for the bottom and side panels. Coating on plain steel is also available for bridges in urban areas and bridges that need to be colored.

Construction work procedures

Panel fabrication procedures

Onsite construction work procedures

(one-sided bolts)

submergence stoppers

Fabrication and erection process

Standard process in the case of a bridge that is 30 meters long, 15 meters wide, and has a bridge surface area of 450 m2 (steel weight: 200 tons)