Latest development of stoker furnace combustion technology

World’s first low excess air combustion system in waste incineration plant

JFE Engineering has achieved stable, low excess air combustion by combining high-temperature air combustion technology with an exhaust gas re-circulation technology.

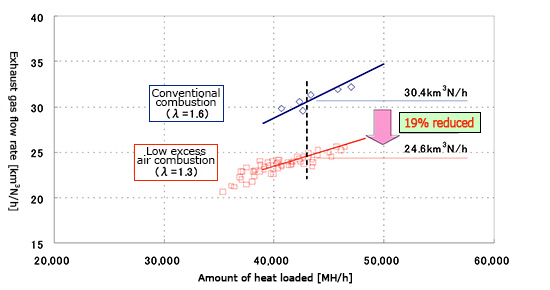

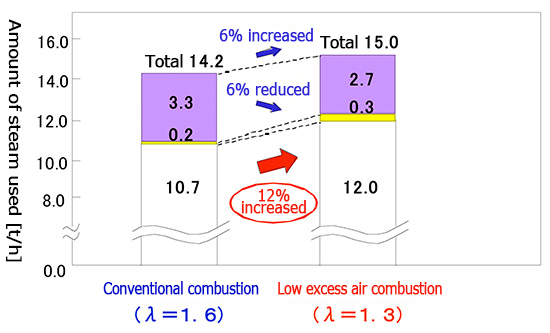

Generally, to incinerate the waste completely, air must be excessively supplied. Reducing the amount of air to burn the waste reduces the amount of heat to be carried out of the system by the exhaust gas and increases heat that can be recovered for electric power generation.

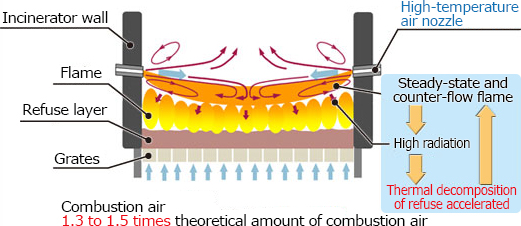

Stable low excess air combustion

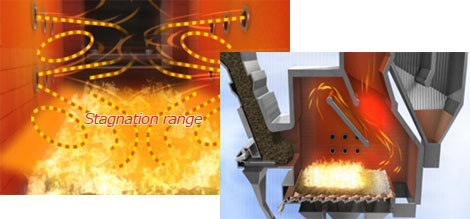

When the mixture of hot air and combustion exhaust gas is blown into the area above the refuse layer, a stable combustion region is formed on the refuse layer. The thermal decomposition of refuse is then accelerated ensuring stable combustion even at a low excess air ratio. As a result, the generation of NOx, CO, and dioxins is reduced, heat loss considerably reduced and exhaust gas recovery efficiency is increased. This technology won the Technology Award from the Combustion Society of Japan in 2003.

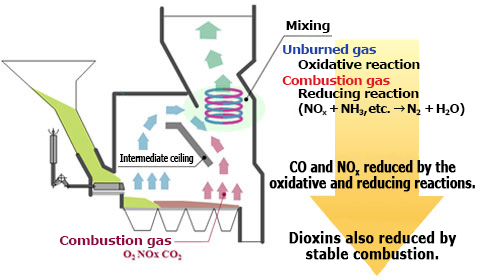

Two-way gas flow

Unburned gas and burned gas are separated inside the combustion chamber and remixed in the mixing chamber achieving complete combustion. This is JFE Engineering’s original design and presents an ideal configuration for the improvement of combustion and reducing hazardous components contained in exhaust gas during the incineration of solid waste. NOx generated in the main combustion zone is reduced and decomposed in the gas mixing chamber by reacting deductively with NH3, HCN, etc. which is self-denitrated in the drying zone. In general, three factors are necessary to reduce dioxins, high Temperature, sufficient retention Time, Turbulence. In our system these conditions are effectively guaranteed in the gas mixing chamber generating considerably reduced dioxins. Another effect of this system is the reduction of corrosion in the boiler due to the acceleration of complete combustion.

Reduce environmental impact

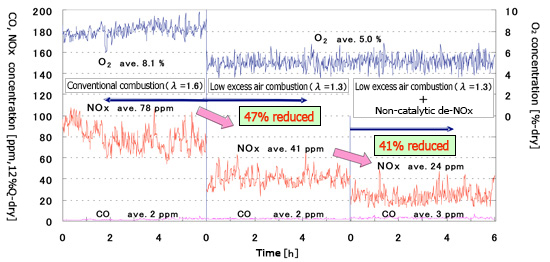

The stable low excess air combustion technology makes it possible to reduce not only exhaust gas volume but the hazardous substances it contains, such as CO and NOx, reducing environmental impact.

Applying the high-temperature air combustion technology reduces the concentration of NOx to almost half of that of conventional systems without increasing unburned gas or CO. By adopting a non-catalytic reduction process, NOx can be reduced to approximately 30% without a catalytic reaction tower.